KK FILM, 50cm x 25m

Product information "KK FILM, 50cm x 25m"

The (almost) all-purpose adhesive!

Product desciption

Appliquéing is a piece of cake with KK FILM: the double-sided, self-adhesive film fixes (temporary) the fabric to be appliquéd without ironing. Coat the appliqué fabric with KK FILM, cut out the desired shape, stick it onto the base fabric, embroider - and you're done!

This is a quick and easy way to produce appliqués with clean edges - no cutting out by hand. The self-adhesive film can also be heat activated - simply transfer the film to the qppliqué fabric and activate it with an iron or ironing press. This increases the adhesive strength and effecto of KK FILM.

This is a quick and easy way to produce appliqués with clean edges - no cutting out by hand. The self-adhesive film can also be heat activated - simply transfer the film to the qppliqué fabric and activate it with an iron or ironing press. This increases the adhesive strength and effecto of KK FILM.

Main Applications:

For cold and hot fusing of appliqués.

For cold and hot fusing of appliqués.

Material Composition:

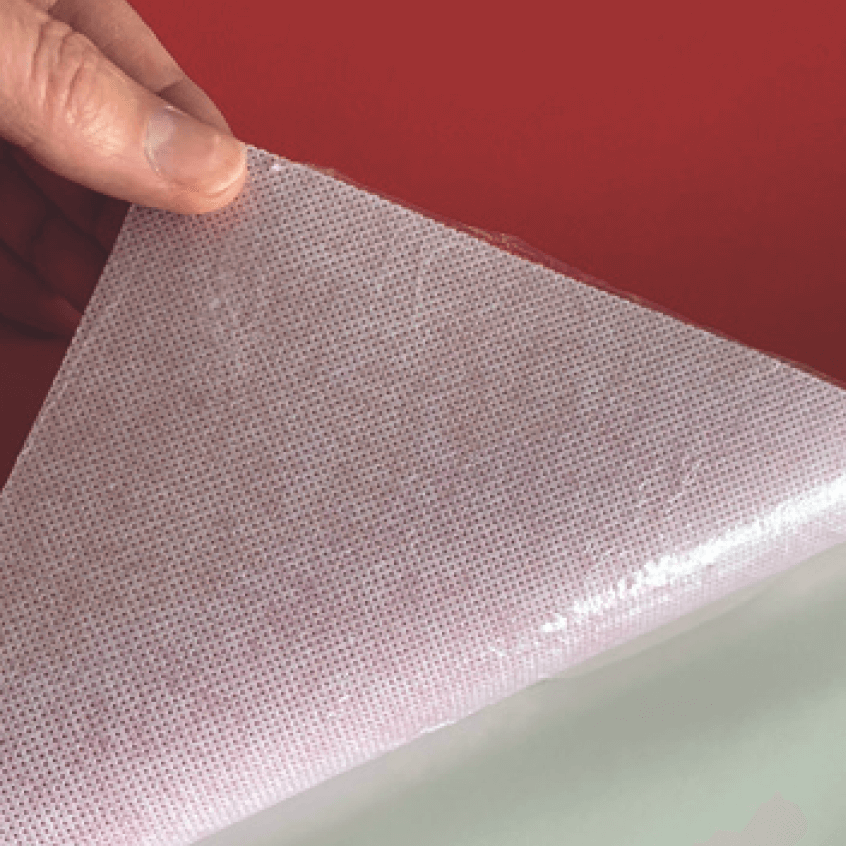

Double-sided, self-adhesive film,

additionally heat activatable

100% polyacrylat

Adhesive: water-based polyacylate.

Solvent-free, ageing-resistant

and permanently elastic

Cover: white silicone paper

Öko-Tex certified:

Downloads

KK FILM - double sided self adhesive film

Application with self-adhesive film:

- 1. Stick KK FILM to the reverse side of the appliqué and press firmly (calender, Welger wood).

- 2. Cut out the appliqué, by hand, laser or cutting plotter.

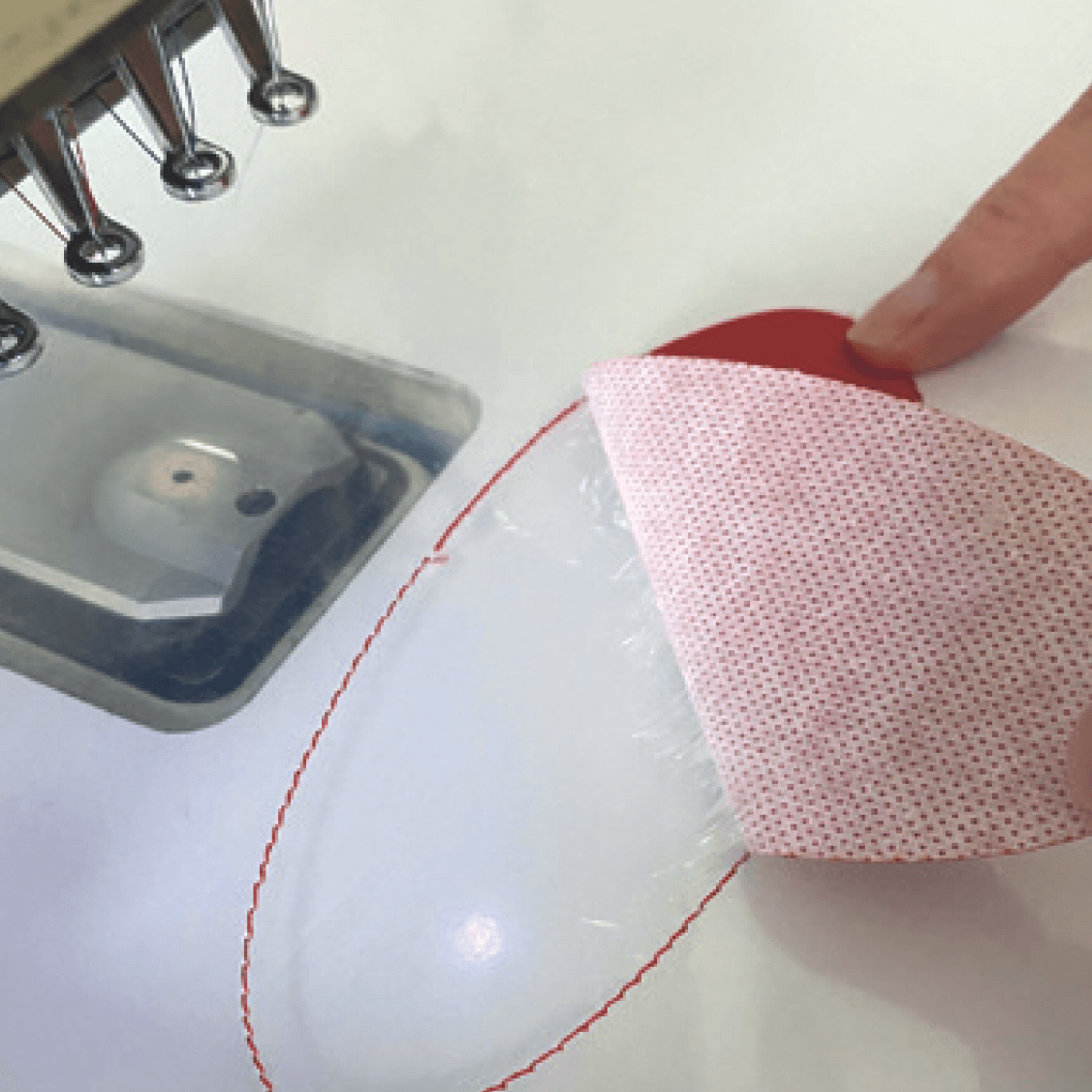

- 3. Remove backing paper. 4. Place the appliqué with the adhesive side on the the base fabric or foil SOLVY 80.

- 5. Finish embroidering the appliqué with satin stitch edge.

- 1. Glue KK FILM to the back of the appliqué fabric. Press the fabric with the ironing press or iron the fabric.

- Temperature: 100 - 120 degrees Celsius

- Pressure: 4 bar

- Duration: 5- 10 s - 2. Cut out the appliqué, by hand, laser or cutting plotter.

- 3. Remove backing paper.

- 4. Fix the appliqué with the adhesive side to the the base fabric or foil SOLVY 80.

- 5. Finish embroidering the appliqué with satin stitch edge.